Filtration systems are important components of any industrial machinery. Keeping the water system clean prevents leaks, contamination, spread of harmful bacteria, and is better for the environment. Because of the chemicals and dangerous products many companies for their daily operations, having good filtering systems is important to create and safe workplace that produces high quality merchandise.

Automatic self-cleaning filters are used in industries across the globe to purify their water sources. The filtration devices come in different sizes and brands to meet the needs of the corporation. There are many benefits to using automated self-functioning filtering devices including:

1. More Efficient

Automatic filters are much more efficient when it comes to removing impurities from the dirty fluids so the water is cleaner afterwards. Unlike manual methods, machine methods clean more watery liquids faster and clean more dirt at a faster rate.

2. Saves Time

Efficient filtration devices save companies time because they are not utilizing staff hours to purify the water. More water is cleaned in less time so it can be recycled and reused to keep the operations moving at a faster and rate.

3. Self-Cleaning

Modern filtering devices have self-cleaning features so the water will always be purified by an uncontaminated device. Corporation leaders can feel a sense of reassurance and security knowing they are using an effective cleaning system. Automated screen filters are beneficial to businesses. Designated cleaning times do not have to be scheduled and filtered water does not have to be tested regularly for contaminants that can seep in when the filters are unclean.

4. Cost Effective

At a time when most businesses are trying to find ways to cut their spending and lower their overhead expenses, automatic filtering systems have many cost-effective benefits. First, they use far less energy to purify the liquids so they reduce the energy costs.

They reduce payroll expenses because staff are not needed to manually filter the water. The self-functioning devices require less maintenance because they are programmed to perform much of he upkeep themselves so industry bosses also save in maintenance costs.

5. Eco-Friendly

Mechanical filters are better for the environment in many ways. They are made from reusable materials so less natural resources are needed to construct each device. They filter more impurities from the dirty water so there is less risk of contaminates seeping into the environment. They do not endanger the planet with harmful emissions that pollute the airways.

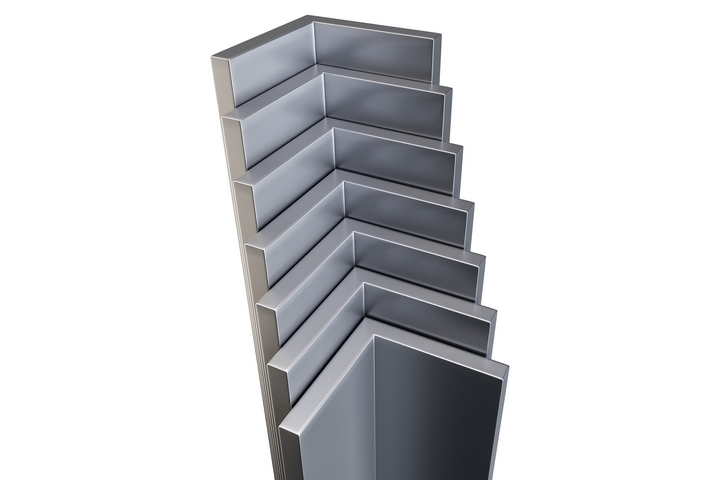

6. Stainless Steel

Filtrations systems are made from stainless steel so they last longer than other filtering systems. Using this natural material is beneficial to both the industry and the planet. Steel is one of the strongest materials on the planet. There is far less risk of breakage or cracking from ongoing wear and tear so managers do not have to replace the filter as frequently as they would with other types. It also reduces the risk of accidental leaks and contamination.

Steel is also a reusable material so filters can be made from recycled steel. Older units can also be reused to make newer models or other devices so less natural resources need to be taken from earth.

Corporation leaders looking for efficient filtration systems can benefit from using an automated, self-cleaning filtering device for their business needs. The automatic systems are made of stainless steel so they are designed to last. The self-cleaning features save in time and resources because staffing hours are not required to clean the waters and machinery. Business owners can purchase a filter system designed to meet their specific industry and pollutant removing needs so the water will always be cleaned thoroughly.